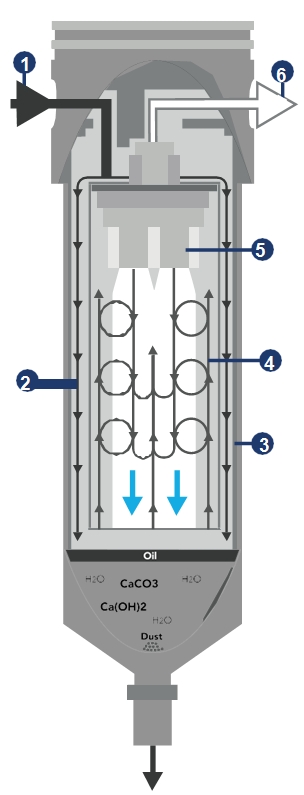

Filtdryer® is a unique technology combined "all-in-one" device to remove condensate, oil and particulate matters from systems of compressed air and technical gasses according ISO 8573.

Water removal > 99.9999%

Dirt removal up to 0.2 µm> 90%

Oil removal 0.01 mg/m3 > 91%

No loss of efficiency depending on pressure and flow

Zero operating costs (equipment without filter inserts)

We offer a complete product range of Filtdryer® separators with a pressure up to 70 bar and a flow rate from 60 l/min. More demanding applications, such as external installations up to -40 ° C or up to 70 bar or even microfiltration, please consult with our techniques.

(1) Polluted air enters the port through the primary chamber where the directional changes of the flow cause cyclone rotation of the air

(2) The air passes through small rings that cause rapid expansion. In this process, up to 98% of the liquid phase is removed

(3) The liquid phase drops to the bottom of the filter unit where it is collected and then forged (manually or automatically)

(4) The air then passes through a precisely designed multistage separation cascade where particle aggregation occurs and thus separates from the medium

(5) The compressed air is then cleaned and the remaining aerosol particles are removed

(6) Clean and dry compressed media can already be used for given applications